معلومات ذات صله

استشر الولايات المتحدة

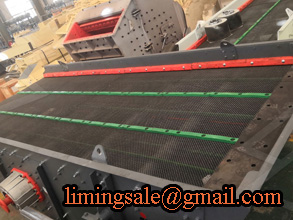

بصفتنا مصنعًا عالميًا رائدًا لمعدات التكسير والطحن ، فإننا نقدم حلولًا متطورة وعقلانية لأي متطلبات لتقليل الحجم ، بما في ذلك إنتاج المحاجر والركام والطحن ومحطة تكسير الحجارة الكاملة. نقوم أيضًا بتوريد الكسارات والمطاحن الفردية وكذلك قطع غيارها.

A multicomponent model for the vertical spindle mill

2016年3月10日· In this paper, a modified Hardgrove mill, with the addition of a power meter, is used to simulate the grinding process of vertical spindle pulverizer Binary2015年3月1日· The most significant difference between the MPS and Emill designs is the grinding mechanism The MPS mill uses a three rollerrace system instead of the 10Modelling of vertical spindle mills Part 2: Integrated

A multicomponent model for the vertical spindle mill

2016年3月10日· Vertical spindle mills (VSMs) are widely utilised in coal power plants that account for more than 40% of the electrical energy generated worldwide These mills can2015年3月1日· In this paper, a modified Hardgrove mill, with the addition of a power meter, is used to simulate the grinding process of vertical spindle pulverizer BinaryModelling of vertical spindle mills Part 2: Integrated models for E

Vertical Grinder From Bourn & Koch The All New MT3

Learn more about our new MT3 vertical grinder MT3 can grind, mill, AND turn, making it the right choice for your today and tomorrow! Skip to primary navigation; 95mm HSK100A Turning Spindle: 67" Max Grinding Wheel OD: High Capacity Oriented Spindle: 350mm HSK63A Turning Spindle: 4400 lbs Max Workpiece:Similar to the ring and ball mill, the vertical spindle roller mill uses large "tires" to crush the coal These mills are usually found in utility plants Raw coal is gravityfed through a central feed pipe to the grinding table where it flows outwardly by centrifugal action and is ground between the rollers and tablePulverizer

An investigation of performance characteristics and

2020年8月12日· Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining2015年3月1日· Mill description Three different vertical spindle mill designs were investigated and modelled as a part of the AsiaPacific Partnership on Clean Development and Climate program (APP) funded by the Australian Government Department of Resources, Energy and Tourism All are called vertical spindle mills reflecting their driveModelling of vertical spindle mills Part 2: Integrated models for E

Modelling of vertical spindle mills Part 1: Submodels for

2015年3月1日· Grinding of coal to this level of fineness is referred to as coal pulverisation The Vertical Spindle Mill (VSM) is one of the most popularly used grinding devices for pulverised fuel (PF) generation in coalfired power stations worldwide According to published figures, coal pulverisation is an energy intensive process2022年1月23日· This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters onAnalysis and Optimization of Grinding Performance of Vertical

Power Mills | Mill Technology | GE Steam Power

For nearly 100 years—ever since pulverized coal combustion was adapted for power generation—GE has been a leader in coal mill technology for the power industry That leadership continues today with the world’s largest fleet of installed power milling equipment Licenses for our milling technology can be found in all coalpowered regions2011年8月1日· Pulverizers prepare raw fuel by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to boiler burners for combustion In Part I ofPulverizers 101: Part I POWER Magazine

Vertical Grinders | UNITED GRINDING North America

UNITED GRINDING is your solutions partner, with products and services designed to assist you throughout the life cycle of your CNC grinding machine, including equipment sales, installation, training, applications support, preventive and predictive maintenance, parts and repair services If you have a project you'd like to discuss, our team willa main spindle in question (maximum speed, radial and axial rigidities, main spindle size, required accuracies, 1Bearing Arrangement for Main Spindles Table 51 Typical examples of bearing arrangements for main spindles Bearing arrangement for main spindle Bearing type [Type !] Tapered roller bearing + Tapered roller bearing +5 Bearing Arrangements and Structures of Bearings for Main

Vertical spindle All industrial manufacturers

Find your vertical spindle easily amongst the 43 products from the leading brands (Fiamgroup, GFMS GF Machining Solutions, NORELEM,) on DirectIndustry, the industry specialist for your professional purchasesGrinding Mill Bead mills are mechanical grinders built up with numerous shafts or trays in which the large molecules are broken into micro components with grinding sheer force which rotates around 70 rpm speed The rotational speed of the vertical spindle mill affects the operating conditions of the grinding unitGrinding Mill an overview | ScienceDirect Topics

Horizontal vs Vertical Milling and Turning: What Are

2020年1月24日· The turret mill is an extremely versatile device but it can be limited by the size of the pieces it produces Bed milling machine Bed milling machines move the materials along the horizontal axis with a2016年3月10日· A multicomponent model of vertical spindle mill is developed • Interlinked comminution and classification operations in the mill are simulated • Particle size distributions and flowrates in all the streams are estimated accurately • Density distributions in these streams are also predicted reasonably well •A multicomponent model for the vertical spindle mill

Modelling of vertical spindle mills Part 2: Integrated models

2015年3月1日· (4) and (5), eg in modelling batch grinding using a modified Hardgrove mill (Shi, 2014), the vertical spindle mill modelling (Kojovic et al, 2015; Shi et al, 2015a) and ball mill modelling (Shi2015年3月1日· Grinding of coal to this level of fineness is referred to as coal pulverisation The Vertical Spindle Mill (VSM) is one of the most popularly used grinding devices for pulverised fuel (PF) generation in coalfired power stations worldwide According to published figures, coal pulverisation is an energy intensive processModelling of vertical spindle mills Part 1: Submodels for

A specific energybased ball mill model: From batch grinding to

2016年2月1日· Introduction A specific energybased size reduction model for batch grinding ball mills has been developed (Shi and Xie, 2015) The objective of this work was to overcome the limitations in the existing JKMRC (Julius Kruttschnitt Mineral Research Centre) perfect mixing ball mill model, including the use of a set of default breakage2017年4月1日· Indeed, according to Boulvin et al [44], experimental data from a grinding circuit show that mill throughput impacts the separating curve A recent experimental study on parameters affecting the VRM performance shows a correlation between product fineness and dynamic separator speed, mill throughput, and the rollers hydraulicOperational parameters affecting the vertical roller mill

Milling Machine Accessories | McMasterCarr

Designed for precision grinding and inspection, the construction of these vises ensures workpieces are held perfectly square For recesses, pockets, and workpieces that are too large or awkward to fit under a vertical mill, these attachments reduce the need for special tooling and fixturing by turning the spindle 年3月1日· Process 4445 (1996) 569581 Component wear in vertical spindle mills grinding coal J Sligar ' Pacific Power, Sydney, Australia Abstract This paper reports on the contribution of a number of material coal properties and machine operating parameters to the wear of vertical spindle mill components This assists in the evaluation of mills andComponent wear in vertical spindle mills grinding coal