معلومات ذات صله

استشر الولايات المتحدة

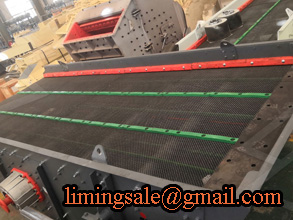

بصفتنا مصنعًا عالميًا رائدًا لمعدات التكسير والطحن ، فإننا نقدم حلولًا متطورة وعقلانية لأي متطلبات لتقليل الحجم ، بما في ذلك إنتاج المحاجر والركام والطحن ومحطة تكسير الحجارة الكاملة. نقوم أيضًا بتوريد الكسارات والمطاحن الفردية وكذلك قطع غيارها.

Ball Mill Shell Mining and Mineral Processing Equipment Supplier

Ball mill shell is a large steel part made of steel plate Different specifications of steel balls are added into the shell cylinder When the ball mill is working, the steel balls rotates with the shell under the action of friction force and inertia forceThe ball mill contains a hollow cylindrical shell that rotates about its axis This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it Ball mills are classified as attritor, horizontal, planetary, high energy, or shakerBall Mill an overview | ScienceDirect Topics

Energy efficient cement ball mill from

Customer story Ball mill upgrade cuts energy consumption by 25% Our ball mills for cement grinding deliver high grinding efficiency with reduced energy consumption and low maintenance 4000+ references worldwideShell linings for ball mills are process relevant components, they lift the ball charge and protect the mill shell during grindingChristian Pfeiffer shell lingins for ball mills · Christian Pfeiffer

Energy efficient cement ball mill from

PulpMax™ composite mill liners can lower costs and improve throughput rates Customer story Ball mill upgrade cuts energy consumption by 25% Our ball mills for cement grinding deliver high grinding efficiency with reduced energy consumption and low maintenance 4000+ references worldwide2012年6月1日· A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation It consists of one or more rotating cylinders partially filled with grinding balls (made(PDF) Grinding in Ball Mills: Modeling and Process

Ball milling: a green technology for the preparation

The formation of cellulose crystals by ball mill assisted hydrolysis was also reported by Tian and coworkers, who described the preparation of microcrystalline cellulose (MCC) from eucalyptus pulp by mercerization2023年2月15日· High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10% 4 when the moisture is greater than 5%, the ball mill will be unable to perform the grinding operation 5 The bearing of the ball mill is overheated and the motor is overloaded17 Signs of Problems with Ball Mills: Quickly Remove Hidden Troubles

Ball Mill Shell Mining and Mineral Processing Equipment Supplier

Ball mill shell is a large steel part made of steel plate Different specifications of steel balls are added into the shell cylinder When the ball mill is working, the steel balls rotates with the shell under the action of friction force and inertia force The material contained in the ball mill is crushed and finely ground by gravity 1The scope of ball mill installation services includes: Replacement or reversal of girth gear and pinion, drive included Replacement of mill sections or head walls Change of inlet and outlet cones Change of diaphragms and liners Repair & refurbishment By employing our onsite mobile machining tools we carry out repairOnsite services for ball mills

Ball Mill | PDF SlideShare

2008年11月18日· 5 Abstract The Ball mill is one of the most important equipment in the world of chemical engineering It is used in grinding materials like ores, chemicals, etc The types of ball mills: batch ball mill and continuous ball mill with different grinding media and different design depend on the nature of the input material and the nature of theAGICO Cement Ball Mill Shell The ball mill shell is a large casting steel parts which made of steel thickened plates It is antivibration, stable, soundproof and safe Different specifications of steel balls are added into the ball mill shell cylinder When the ball mill is working, the steel balls rotates with the shell under the action ofBall Mill Shell AGICO Cement Plant

Christian Pfeiffer Ball Mill BAM for Industrial Minerals · Christian

The BAM ball mill for industrial minerals is designed to be particularly efficient thanks to our process knowhow This is because the efficiency of a mill depends on its internals All parts of the mill, the diaphragm, the shell lining and the ball charge, have been continuously developed inhouse for nearly a century, which is the basis of our expertiseFLS Ball Mill Liners Learn how to improve the performance and reliability of your ball mills with our durable and innovative liners Our liners are designed to suit different grinding applications and reduce downtime Download our brochure and discover the benefits of FLS Ball Mill LinersIG PERFORMANCE PARTS Mill Liners for Ball Mills Increase

Ball mill Superior cement quality, More fl exibility, higher

4 Ball mill for cement grinding Ball mill for cement grinding 5 Outlet grate with adjustable lifters Slide shoe bearing Mill shell with weldedin The mill body consists of an allwelded mill shell and a Tsectional weldedup slide ring at either end, the cylindrical part of which is welded onto the ends of the shellAny hole on the mill shell weakens the shell structure and is a potential leakage point In addition, noise emission during operation is increased Nevertheless, each type of fastening has its justification For coarse grinding in the first chamber, we prefer screwed solutions for DIN plates to ensure maximum availability and operationalChristian Pfeiffer shell lingins for ball mills · Christian Pfeiffer

(PDF) Investigation of the effect of industrial ball mill liner type on

2021年6月21日· Effects of mill shell liner type on charge shoulder, toe, impact, and head points, also on head height and impact zone length as well as on the creation of cascading, cataracting, and centrifuging6001 STAPLES MILL ROAD, 232284923, RICHMOND, US +1 8042641900 Get Directions Offers6001 STAPLES MILL ROAD Shell

Ball Mill Adalah? Prinsip Kerja, Bagian, Komponen Dan Fungsinya

2022年10月5日· Ball Mill adalah suatu mesin yang berbentuk silinder (tabung) dan berfungsi untuk menggiling material kasar menjadi material yang halus Mesin ini memanfaatkan bolabola keras untuk menumbuk dan menggesek material kasar sehingga bisa menjadi halus Ball Mill menjadi salah satu mesin yang sangat penting dalamSmall Ball Mills – Canada We sell Small Ball Mills from 2′ to 6’ (600 mm X 1800 mm) in diameter and as long as 10″ (3000 mm) in length The mills are manufactured using a flanged mild steel shell, cast heads, overflow discharge, removable man door, spur type ring gear, pinion gear assembly with spherical roller bearings, replaceable roller bronzeSmall Ball Mill 911 Metallurgist

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL METHODOLOGY

2016年4月25日· This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder The cylindrical jar is used as a mill that would rotate theMill Lining Systems Trelleborg has been providing mill lining systems since 1920 The focus is on working with our customers to provide incremental improvement to enhance mill availability, increasing efficiency and reducing energy consumption Full lining kits are designed and supplied including Lifter bars, shell plates, pulp liftersMill Lining Systems | FluidHandling Trelleborg

EVERY COMPONENT OF BALL MILL DETAILED & EXPLAINED

1Axial/radial runout 2Alignment of the drive trains 3Uneven power splitting 4Centre distances variable 5Face load distribution 6Sealing of the girth gear 7Girth gear is through hardened only, fatigue strength is limited Dynamic behaviour A lot of individual rotating masses risk of resonance vicinities2020年9月1日· Mechanochemical technique aims to strike a balance between defect formation via ball milling and size adjustment of a solid grain to nanoscale (<1000 nm) (Ullah et al, 2014)During the process, a highenergy mill is employed and a specific powder charge is placed along with a milling medium (Lin et al, 2017)The kinetic energyBall milling as a mechanochemical technology for fabrication of